Chen, Zhichao & Wang, Qingxiang & Wang, Bingnan & Zeng, Lingyan & Che, Miaomiao & Zhang, Xin & Li, Zhengqi, 2017." Strategic combustion technology with exhaust tube vortex flame: Combined effect of biomass co-firing and air-staged combustion on combustion characteristics and ash deposition," Choi, Minsung & Kim, Kibeom & Li, Xinzhuo & Deng, Kaiwen & Park, Yeseul & Seo, Minseok & Sung, Yonmo & Choi, Gyungmin, 2020." A novel corner-fired boiler system of improved efficiency and coal flexibility and reduced NOx emissions,"Īpplied Energy, Elsevier, vol.

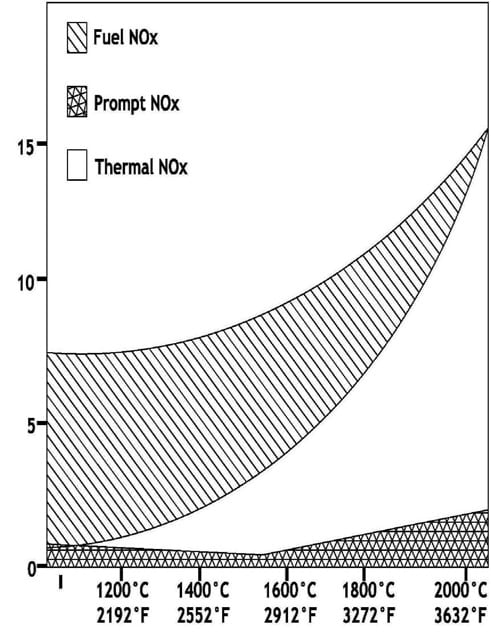

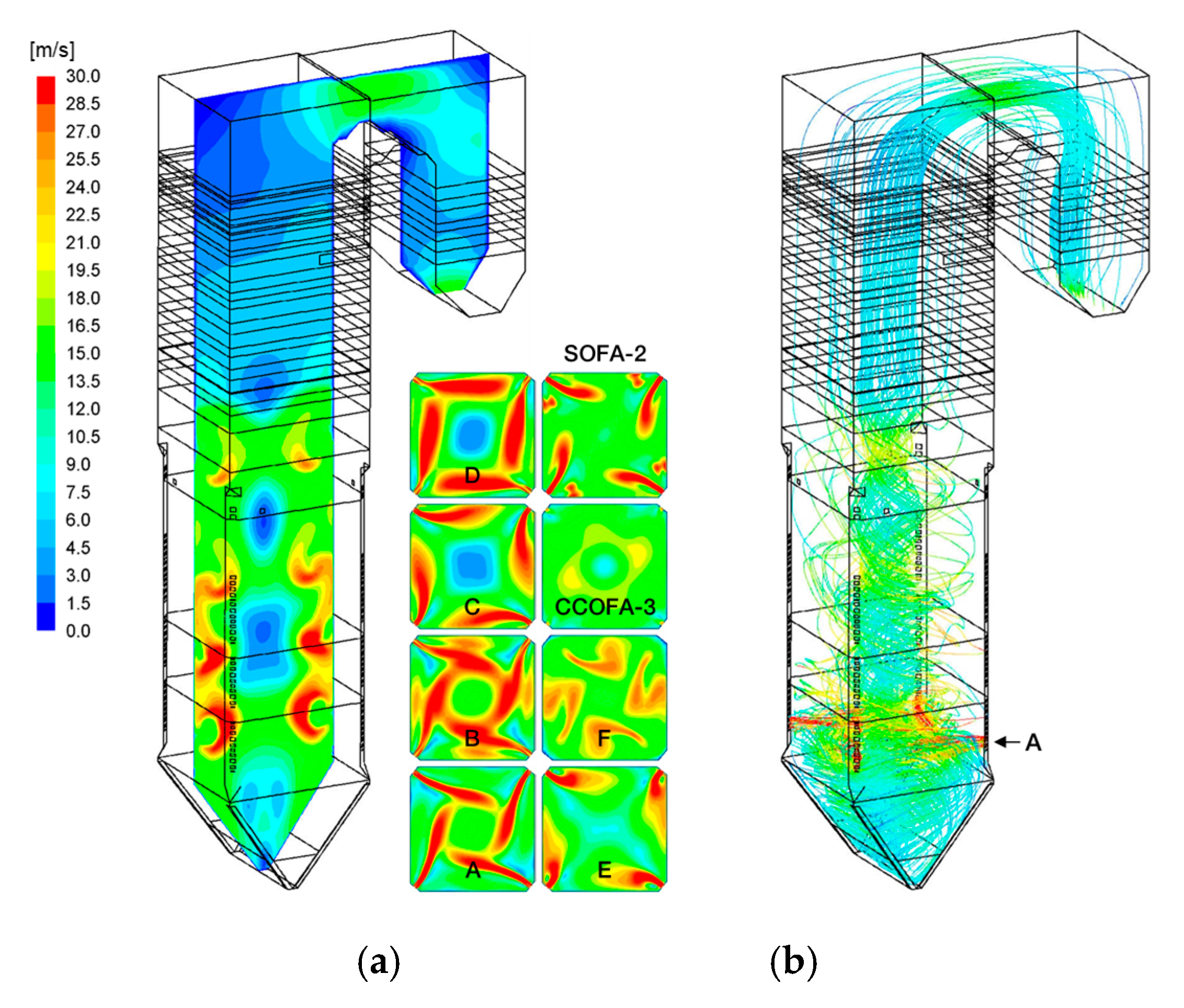

Although the non-premixed injection mode has a slightly lower burnout performance than other injection modes, it is determined to be more effective in reducing the total amount of NOx emissions. The ETV structure enhanced the coal particle uniformity and expanded the reaction zone, consequently reducing the area of the local high-temperature region. An exhaust tube vortex (ETV) structure with a tulip-shaped IRZ is observed in the non-premixed swirling flame injection mode however, the ETV structure is not observed in the other injection modes. The total amount of NOx emissions at the boiler outlet are 205.0 and 551.2 ppm O2) for the co-swirling and counter-swirling flames, respectively the deNOx efficiency is 62.8%. In addition, the high uniformity of coal particles is maintained in all horizontal cross-sections. The co-swirling flame exhibits a tulip-shaped inner recirculation zone (IRZ), which increases the coal particle residence time: 1.61 s and 1.45 s for co-swirling and counter-swirling flames, respectively. A numerical evaluation was performed to investigate the effects of swirl arrangement (co-swirling and counter-swirling flows) and coal injection mode (non-, fully-, and partially-premixed with swirling flow) on the flame structure, coal particle uniformity, burnout performance, and nitrogen oxide (NOx) emissions in a 16-kWth coal-fired boiler.

0 kommentar(er)

0 kommentar(er)